At present, many diaphragm pump manufacturers price gap is very big.

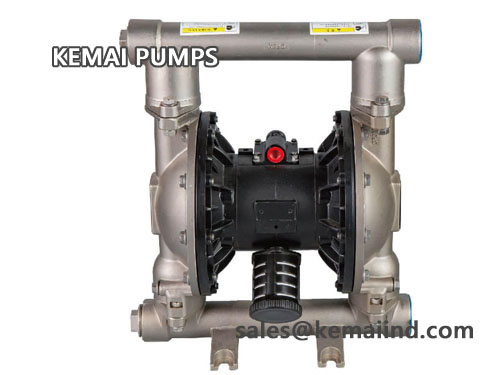

Kemai pump is a professional company.

Pump low price, high quality.

Long-term cooperation and good partner.

Widely used in food, petroleum, chemical, electric power…

1) the pump will not overheat: compressed air as the power, in the exhaust is a process of expansion and heat absorption, pneumatic pump operation temperature is reduced, no harmful gas discharge.

2) will not produce electric spark: pneumatic diaphragm pump without electric power, grounding and avoid electrostatic spark.

3) can pass through the liquid containing particles: because of the volumetric operation and the inlet for the ball valve, so it is not easy to be blocked.

4) The shear force of the material is very low: how to suck in and how to spit out during the operation, so the agitation of the material is small, suitable for the transport of unstable substances.

5) The flow can be adjusted, and the throttle valve can be installed at the material outlet to adjust the flow.

6) It has the function of self-imbibition.

7) To be able to operate without danger

Two, the pump flow is too low will lead to slow work or stop

1, check whether the pump body is free plaque, adjust the inlet pressure of compressed air.

Reduce the working speed of the pump body to adjust the viscosity and concentration of larger liquids.