Beam Coupling For Servo Motor, BCM Model beam flexible coupling bore: 3,4,5,6, 6.35 , 8,9, 9.525 ,10,11,12, 12.7 ,14,15,16.

1:Integrated sturcture,the ovrall use of high-strength aluminum alloy.

2:Flexible action to compensate radial,angular and axial misalignment.

3:Seamless shaft and sleeve connection,suitable for reversing.

4:Jack Screw type,Main use for Servo Motor.

BCM Series

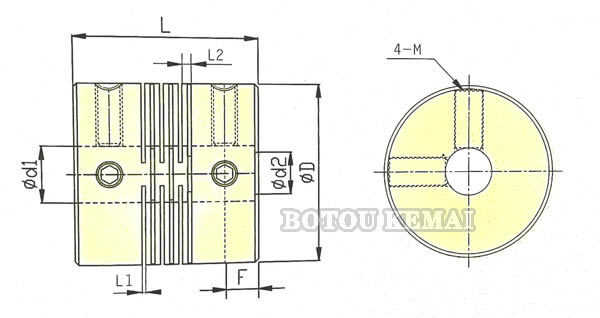

BCM-Outside diameter X Total length – d1 bore X d2 bore

Example: BCM-39X30-10X10

BC: Beam coupling

M: Servo Motor

39: Outside diameter

30: Total length

10: d1 bore diameter

10: d2 bore diameter

| Model | d1 d2

Bore |

ΦD | L | L1 | L2 | F | M | Wrench Torque

(N.M) |

| BCM-16X17.5 | 3,4,5,6 | Φ16 | 17.5 | 0.5 | 1 | 3 | 4-M3X5 | 0.7 |

| BCM-19X20 | 3,4,5,6, 6.35 ,8 | Φ19 | 20 | 0.5 | 1.18 | 3.4 | 4-M3X6 | 0.7 |

| BCM-24X25 | 4,5,6, 6.35 ,7,8,10 | Φ24 | 25 | 0.55 | 1.49 | 4.25 | 4-M4X6 | 1.7 |

| BCM-29X30 | 5,6, 6.35 ,7,8,9, 9.525 ,10,11,12 | Φ29 | 30 | 0.55 | 1.81 | 5.1 | 4-M4X8 | 4 |

| BCM-34X35 | 8,9, 9.525 ,10,11,12, 12.7 ,14,15,16 | Φ34 | 35 | 0.8 | 2.09 | 6 | 4-M5X10 | 4 |

| Model | Rated torque

(N.M) |

Maximum torque

(N.M) |

Allow Radial direction

(mm) |

Allow angle

(°) |

Allow Axis

(mm) |

Maximum speed

(rpm) |

Static torsional stiffness

(N.M/rad) |

Moment of inertia

(kg.M2) |

Flexible colloidal material | Surface Treatment | Weight

(g) |

| BCM-16X17.5 | 0.5 | 1 | 0.05 | 0.5 | ±0.1 | 24000 | 200 | 2.8×10-7 | High strength aluminum alloy | Oxidation treatment | 7 |

| BCM-19X20 | 1 | 2 | 0.05 | 0.5 | ±0.1 | 20000 | 270 | 6.2×10–6 | 10 | ||

| BCM-24X25 | 1.5 | 3 | 0.05 | 0.5 | ±0.1 | 16000 | 790 | 2.0×10–6 | 22 | ||

| BCM-29X30 | 2 | 4 | 0.05 | 0.5 | ±0.1 | 13000 | 1400 | 5.2×10–6 | 40 | ||

| BCM-34X35 | 3 | 6 | 0.05 | 0.5 | ±0.1 | 11000 | 2200 | 1.1×10–5 | 64 |