Single beam coupling bore: 3,4,5,6,6.35 ,8,9, 9.525 ,10,11,12,12.7 ,14,15,16,19,20,22,24,25 mm. Material: aluminum.

1:Integrated structure,the overall material used in hight-strenth aluminum.

2:Elastomer compensate radial,angular and axial misalignment.

3:Spring-loaded design with cushioning effect.

4:Jack screw.

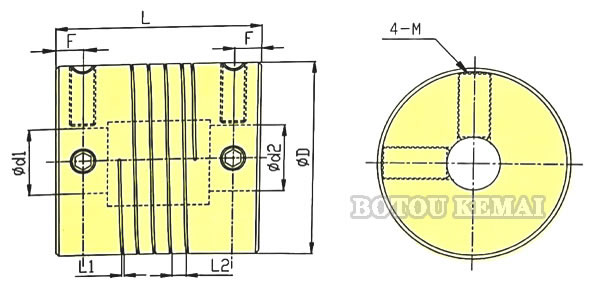

SBC Series

SBC-Outside diameter X Total length – d1 bore X d2 bore

Example: SBC-25X32-9X9

S: Sigle

BC: Beam coupling

25: Outside diameter

32: Total length

9: d1 bore diameter

9: d2 bore diameter

| Model | d1 d2

Bore |

ΦD | L | L1 | L2 | F | M | Wrench Torque

(N.M) |

| SBC-15.5X21 | 3,4,5,6 | Φ15.5 | 21 | 0.4 | 2 | 3.3 | 4-M3X5 | 0.7 |

| SBC-15.5X23 | 3,4,5,6 | Φ15.5 | 23 | 0.4 | 2 | 3.6 | 4-M3X5 | 0.7 |

| SBC-16X23 | 3,4,5,6 | Φ16 | 23 | 0.4 | 2 | 3.6 | 4-M4X5 | 1.7 |

| SBC-17.5X23 | 4,5,6, 6.35 | Φ17.5 | 23 | 0.4 | 2 | 3.6 | 4-M4X6 | 1.7 |

| SBC-18X25 | 4,5,6, 6.35 ,8 | Φ18 | 25 | 0.4 | 2 | 4.1 | 4-M4X6 | 1.7 |

| SBC-19.1X19.1 | 4,5,6, 6.35 ,8 | Φ19.1 | 19.1 | 0.4 | 2 | 3 | 4-M4X6 | 1.7 |

| SBC-19.5X25.4 | 6, 6.35 ,8,9, 9.525 ,10 | Φ19.5 | 24.5 | 0.4 | 2 | 3.6 | 4-M4X8 | 1.7 |

| SBC-25X32 | 6, 6.35 ,8,9, 9.525 ,10,11,12 | Φ25 | 32 | 0.4 | 2.75 | 4.5 | 4-M4X8 | 1.7 |

| SBC-25.4X25.4 | 6, 6.35 ,8,9, 9.525 ,10,11,12 | Φ25.4 | 25.4 | 0.4 | 2.75 | 3.7 | 4-M4X8 | 1.7 |

| SBC-28.6X28.6 | 8,9, 9.525 ,10,11,12,14 | Φ28.6 | 28.6 | 0.4 | 2.75 | 4.2 | 4-M4X8 | 1.7 |

| SBC-32X32 | 8,9, 9.525 ,10,11,12,14,15,16 | Φ32 | 32 | 0.4 | 2.75 | 5.2 | 4-M5X10 | 4 |

| SBC-38.1X38.1 | 8,10,11,12, 12.7 ,14,15,16,19 | Φ38.1 | 38.1 | 0.4 | 3 | 5.2 | 4-M5X10 | 4 |

| SBC-50X50 | 12, 12.7 ,14,15,16,19,20,22,24,25 | Φ50 | 50 | 0.5 | 3.5 | 8.5 | 4-M6X12 | 7 |

| Model | Rated torque

(N.M) |

Maximum torque

(N.M) |

Allow Radial direction

(mm) |

Allow angle

(°) |

Allow Axis

(mm) |

Maximum speed

(rpm) |

Static torsional stiffness

(N.M/rad) |

Moment of inertia

(kg.M2) |

Flexible colloidal material | Surface Treatment | Weight

(g) |

| SBC-15.5X21 | 1 | 1 | 0.15 | 3 | ±0.2 | 25000 | 80 | 2.8×10–7 | High strength aluminum alloy | Oxidation treatment | 7.7 |

| SBC-15.5X23 | 1 | 1 | 0.15 | 3 | ±0.2 | 25000 | 80 | 2.9×10–7 | 9.3 | ||

| SBC-16X23 | 1.1 | 2.2 | 0.15 | 3 | ±0.2 | 25000 | 82 | 3.0×10–7 | 11 | ||

| SBC-17.5X23 | 1.2 | 2.4 | 0.15 | 3 | ±0.2 | 25000 | 85 | 3.5×10–7 | 12.7 | ||

| SBC-18X25 | 1.3 | 2.6 | 0.15 | 3 | ±0.2 | 24000 | 130 | 4.7×10–7 | 15 | ||

| SBC-19.1X19.1 | 1.4 | 2.8 | 0.15 | 3 | ±0.2 | 24000 | 91 | 7.2×10–7 | 11.6 | ||

| SBC-19.5X25.4 | 1.5 | 3 | 0.15 | 3 | ±0.2 | 19000 | 150 | 8.1×10–7 | 16 | ||

| SBC-25X32 | 2.8 | 5.6 | 0.15 | 3 | ±0.2 | 14000 | 400 | 2.4×10–6 | 32 | ||

| SBC-25.4X25.4 | 2 | 4 | 0.15 | 3 | ±0.2 | 14000 | 360 | 2.3×10–6 | 26 | ||

| SBC-28.6X28.6 | 3 | 6 | 0.15 | 3 | ±0.2 | 13000 | 380 | 2.5×10–6 | 39 | ||

| SBC-32X32 | 4 | 8 | 0.15 | 3 | ±0.2 | 11000 | 420 | 2.6×10–5 | 57 | ||

| SBC-38.1X38.1 | 6.5 | 13 | 0.15 | 3 | ±0.2 | 9500 | 450 | 3.0×10–5 | 97 | ||

| SBC-50X50 | 20 | 40 | 0.15 | 3 | ±0.2 | 8000 | 785 | 8.1×10–5 | 220 |