Stainless Steel Spiral Beam Coupling BCCS Series. Integrated structure,the overall use of stainless steel. High Quality with Best Price.

1:Integrated structure,the overall use of stainless steel.

2:Stainles steel has high corrosion and fatigue resistance.

3:Seamless shaft and sleeve connection,suitable for reversing.

4:Clamp type.

BCCS Series

BCCS-Outside diameter X Total length – d1 bore X d2 bore

Example: BCCS-50X71-19X19

BC: Beam coupling

C: Clamp Type

S: Stainless steel

50: Outside diameter

71: Total length

19: d1 bore diameter

19: d2 bore diameter

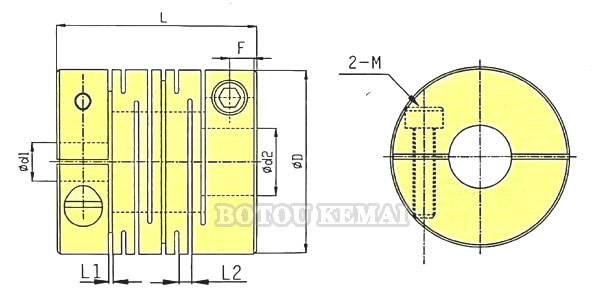

Stainless Steel Beam Coupling Drawing

| Model | d1 d2

Bore |

ΦD | L | L1 | L2 | F | C | M | Wrench Torque

(N.M) |

| BCCS-16X21 | 3,4,5,6, 6.35 | Φ16 | 21 | 0.5 | 1.3 | 2.85 | 5.2 | 2-M3x8 | 2.5 |

| BCCS-16X23 | 3,4,5,6, 6.35 | Φ16 | 23 | 0.5 | 1.3 | 2.85 | 5.2 | 2-M3x8 | 2.5 |

| BCCS-19X23 | 3,4,5,6, 6.35 ,8 | Φ19 | 23 | 0.5 | 1.3 | 2.85 | 6.2 | 2-M3x8 | 2.5 |

| BCCS-20X26 | 4,5,6, 6.35 ,7,8 | Φ20 | 26 | 0.5 | 1.4 | 3.93 | 6.2 | 2-M3x10 | 2.5 |

| BCCS-25X25 | 5,6, 6.35 ,7,8,9, 9.525 ,10,11,12 | Φ25 | 25 | 0.7 | 1.7 | 4.8 | 8.2 | 2-M3x10 | 2.5 |

| BCCS-25X31 | 5,6, 6.35 ,8,9, 9.525 ,10,11,12 | Φ25 | 31 | 0.7 | 1.8 | 4.6 | 8.2 | 2-M3x10 | 2.5 |

| BCCS-28.5X38 | 6, 6.35 ,8,9, 9.525 ,10,11,12,14 | Φ28.5 | 38 | 0.8 | 2.1 | 5.63 | 9 | 2-M4x12 | 3.5 |

| BCCS-32X32 | 8,9, 9.525 ,10,11,12,14,15 | Φ32 | 32 | 0.8 | 2.3 | 6.28 | 10.5 | 2-M4x14 | 3.5 |

| BCCS-32X41 | 8,9, 9.525 ,10,11,12,14,15 | Φ32 | 41 | 0.8 | 2.3 | 6.02 | 10.5 | 2-M4x14 | 3.5 |

| BCCS-38X41 | 10,11,12, 12.7 ,14,15,16 | Φ38 | 41 | 0.8 | 2.3 | 6.23 | 12.5 | 2-M5x16 | 8 |

| BCCS-40X50 | 10,11,12, 12.7 ,14,15,16,19,20 | Φ40 | 50 | 0.8 | 2.3 | 7.5 | 13.6 | 2-M5x10 | 8 |

| BCCS-40X56 | 10,11,12, 12.7 ,14,15,16,19,20 | Φ40 | 56 | 0.8 | 2.3 | 7.5 | 13.6 | 2-M5x16 | 8 |

| BCCS-50X50 | 10,11,12, 12.7 ,14,15,16,19,20,22,25 | Φ50 | 50 | 0.8 | 2.9 | 7.22 | 16.5 | 2-M6x25 | 15 |

| BCCS-50X71 | 10,11,12, 12.7 ,14,15,16,19,20,22,25 | Φ50 | 71 | 0.8 | 3.3 | 8.48 | 16.5 | 2-M6x25 | 15 |

| BCCS-63X90 | 14,15,16,19,20,22,25,28,30,35 | Φ63 | 90 | 0.8 | 3.6 | 12.4 | 21 | 2-M8x20 | 30 |

| Model | Rated torque

(N.M) |

Maximum torque

(N.M) |

Allow Radial direction

(mm) |

Allow angle

(°) |

Allow Axis

(mm) |

Maximum speed

(rpm) |

Static torsional stiffness

(N.M/rad) |

Moment of inertia

(kg.M2) |

Flexible colloidal material | Surface Treatment | Weight

(g) |

| BCCS-16X21 | 0.9 | 1.8 | 0.1 | 2 | ±0.2 | 9800 | 84 | 8.2×10-7 | SUS | Polishing processing | 23 |

| BCCS-16X23 | 0.9 | 1.8 | 0.1 | 2 | ±0.2 | 9500 | 84 | 9.0×10-7 | 23 | ||

| BCCS-19X23 | 1.7 | 3.4 | 0.1 | 2 | ±0.2 | 7400 | 240 | 2.3×10–6 | 38 | ||

| BCCS-20X26 | 1.8 | 3.6 | 0.1 | 2 | ±0.2 | 7600 | 245 | 2.5×10–6 | 42 | ||

| BCCS-25X25 | 3.6 | 7.2 | 0.15 | 2 | ±0.2 | 6100 | 720 | 6.3×10–6 | 66 | ||

| BCCS-25X31 | 3.6 | 7.2 | 0.15 | 2 | ±0.2 | 6100 | 330 | 7.1×10–6 | 75 | ||

| BCCS-28.5X38 | 5.4 | 10.8 | 0.15 | 2 | ±0.2 | 5500 | 500 | 7.5×10–6 | 125 | ||

| BCCS-32X32 | 7.2 | 14.4 | 0.15 | 2 | ±0.2 | 5000 | 1300 | 2.2×10–5 | 145 | ||

| BCCS-32X41 | 7.2 | 14.4 | 0.15 | 2 | ±0.2 | 4800 | 850 | 2..7×10–5 | 165 | ||

| BCCS-38X41 | 12.6 | 25.2 | 0.2 | 2 | ±0.2 | 3800 | 900 | 6.1×10–5 | 260 | ||

| BCCS-40X50 | 15 | 30 | 0.2 | 2 | ±0.2 | 3600 | 950 | 7.2×10–5 | 400 | ||

| BCCS-40X56 | 15 | 30 | 0.2 | 2 | ±0.2 | 3600 | 1350 | 9.4×10–5 | 720 | ||

| BCCS-50X50 | 33 | 66 | 0.2 | 2 | ±0.2 | 3200 | 1650 | 11×10–5 | 900 | ||

| BCCS-50X71 | 38 | 76 | 0.2 | 2 | ±0.2 | 3200 | 1650 | 11×10–5 | 900 | ||

| BCCS-63X90 | 50 | 100 | 0.2 | 2 | ±0.2 | 3000 | 2150 | 13.4×10–5 | 1655 |