Single Disc Coupling Aluminum A1C Series bore 3,4,5,6, 6.35 ,7,8,9,10,12,14,15,16,18,19,20,22,24,25,28,30,35,38,40 mm.

Single Disc Coupling KEMAI brand have High precision, designed for servo, stepping motor dsign. OD:16~82mm ; Length: 17~69mm. Bore:3~40mm.

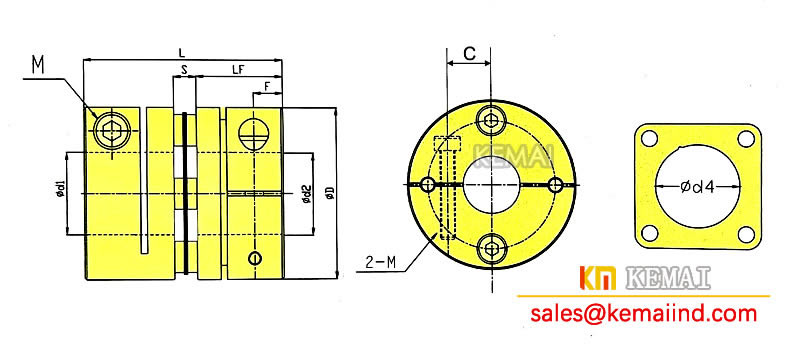

Single Disc Coupling

A1C Series

A1C-Outside diameter X Total length – d1 bore X d2 bore

Example: A1C-56X45-18X20

A: Aluminum

1: Single

C: Clamping Type

56: Outside diameter

45: Total length

18: d1 bore diameter

20: d2 bore diameter

Single Disc Coupling Size

| Model | d1,d2,Bore | ΦD | L | Φd4 | LF | S | F | C | M | Wrench Torque

(N.M) |

| A1C-16×17 | 3,4,5,6, 6.35 | Φ16 | 17 | 6.5 | 7.8 | 3 | 2.65 | 4.6 | 2-M2x8 | 1.5 |

| A1C-19×20 | 3,4,5,6, 6.35 ,7,8,9,10 | Φ19 | 20 | 8.5 | 9 | 2 | 2.2 | 6 | 2-M2.5×10 | 1.5 |

| A1C-26×24 | 4,5,6, 6.35 ,7,8,9, 9.525 ,10,11,12, 12.7 ,14 | Φ26 | 24 | 10.5 | 10.65 | 2.7 | 3.4 | 8.58 | 2-M2.5×10 | 1.5 |

| A1C-26×26 | 4,5,6, 6.35 ,7,8,9, 9.525 ,10,11,12, 12.7 ,14 | Φ26 | 26 | 10.5 | 11.65 | 2.7 | 3.9 | 8.58 | 2-M3x12 | 2.5 |

| A1C-32×28.5 | 6, 6.35 ,7,8,9, 9.525 ,10,11,12, 12.7 ,14,15 | Φ32 | 28.5 | 14.5 | 12.25 | 3.9 | 3.9 | 11 | 2-M3x12 | 2.5 |

| A1C-34×28.5 | 6, 6.35 ,7,8,9, 9.525 ,10,11,12, 12.7 ,14,15 | Φ34 | 28.5 | 14.5 | 12.25 | 3.9 | 3.85 | 11.25 | 2-M3x12 | 2.5 |

| A1C-34×32.5 | 6, 6.35 ,7,8,9, 9.525 ,10,11,12, 12.7 ,14,15 | Φ34 | 32.5 | 14.5 | 14.25 | 3.9 | 4.85 | 11.25 | 2-M4x14 | 3.5 |

| A1C-39×34.5 | 8,9, 9.525 ,10,11,12, 12.7 ,14,15,16,18,19 | Φ39 | 34.5 | 17 | 15.5 | 3.6 | 5.1 | 13.1 | 2-M4x18 | 3.5 |

| A1C-44×34.5 | 8,9, 9.525 ,10,11,12, 12.7 ,14,15,16,18,19,20,22 | Φ44 | 34.5 | 20.5 | 15.5 | 3.6 | 5.1 | 15.5 | 2-M4x20 | 3.5 |

| A1C-50×41.5 | 10,12,14,15,16,18,19,20,22,24,25 | Φ50 | 41.5 | 22.5 | 18 | 5.5 | 5.5 | 17.3 | 2-M5x20 | 8 |

| A1C-56×45 | 12,14,15,16,18,19,20,22,24,25 | Φ56 | 45 | 26 | 19.75 | 5.8 | 6.4 | 19.5 | 2-M5x25 | 8 |

| A1C-68×54 | 15,16,19,20,22,24,25,28,30,35 | Φ68 | 54 | 31 | 23.35 | 7 | 7.7 | 23.5 | 2-M6x35 | 15 |

| A1C-82×69 | 22,24,,28,30,35,38,40 | Φ82 | 69 | 41 | 30 | 8.7 | 9.7 | 28 | 2-M8x35 | 30 |

| Model | Rated torque

(N·M)

|

Maximum

Torque (N·M) |

Allow Radial direction

(mm) |

Allow angle

( °)

|

Allow Axis

(mm) |

Maximum speed

Rmp |

Static torsional

Stiffness (N·M/rad) |

Moment of

Inertia (kg·M2) |

Bushings

Material |

Flexible

colloidal material |

Surface

treatment |

Weigh

g |

| A1C-16×17 | 1 | 2 | 0.1 | 1 | ±0.1 | 10000 | 280 | 2.2×10-7 | Hing-strength

aluminum alloy |

SUS | Oxidation

treatment |

8 |

| A1C-19×20 | 2 | 4 | 0.1 | 1 | ±0.1 | 10000 | 560 | 6.7×10-7 | 11 | |||

| A1C-26×24 | 3.5 | 7 | 0.1 | 1 | ±0.1 | 10000 | 1125 | 2.1×10-6 | 25 | |||

| A1C-26×26 | 3.5 | 7 | 0.1 | 1 | ±0.1 | 10000 | 1125 | 2.2×10-6 | 28 | |||

| A1C-32×28.5 | 8 | 16 | 0.1 | 1 | ±0.1 | 10000 | 2100 | 7.1×10-6 | 46 | |||

| A1C-34×28.5 | 8 | 16 | 0.1 | 1 | ±0.1 | 10000 | 2550 | 7.5×10-6 | 50 | |||

| A1C-34×32.5 | 8 | 16 | 0.1 | 1 | ±0.1 | 10000 | 2550 | 8.0×10-6 | 55 | |||

| A1C-39×34.5 | 15 | 30 | 0.1 | 1 | ±0.1 | 10000 | 3900 | 2.2×10-6 | 81 | |||

| A1C-44×34.5 | 18 | 36 | 0.1 | 1 | ±0.1 | 10000 | 4500 | 2.8×10-5 | 180 | |||

| A1C-50×41.5 | 20 | 40 | 0.1 | 1 | ±0.1 | 10000 | 5000 | 3.5×10-5 | 180 | |||

| A1C-56×45 | 30 | 60 | 0.1 | 1 | ±0.1 | 10000 | 12900 | 1.2×10-4 | 217 | |||

| A1C-68×54 | 60 | 120 | 0.1 | 1 | ±0.1 | 10000 | 25800 | 1.5×10-4 | 348 | |||

| A1C-82×69 | 100 | 200 | 0.1 | 1 | ±0.1 | 10000 | 38700 | 1.8×10-4 | 689 |