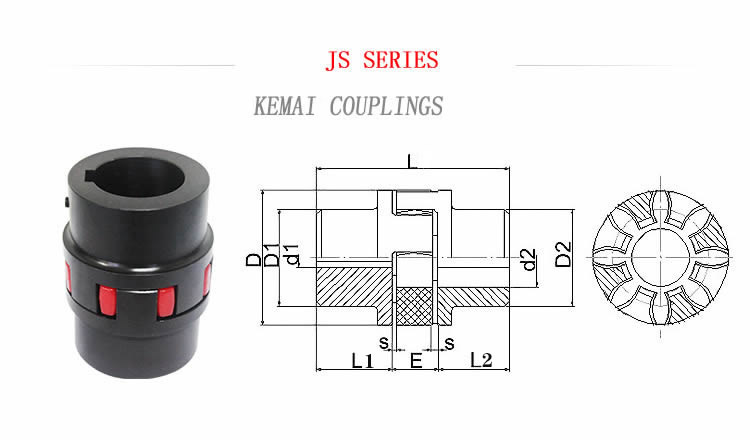

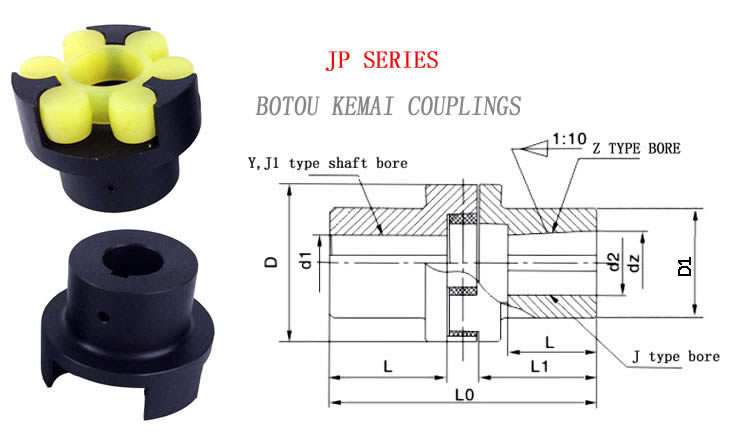

Jaw flexible coupling have two series. JS series model and JP series model.JS series is curved jaw coupling. These shaft coupling main use for mining, chemical, lifting, textile, water pump, fans, etc.

Bore diameter: 6mm~180mm.

Bore length: 38~300mm.

First, we can make flexible coupling according to the size you provide.

1.Compact size,small inertia.

2.Can absorb vibration,angular misalignmengs and shaft end-play

3.Plastic components for flexibility,cushioning,vibration,wear.Operating temperature ≤80℃.

4.Elastic limit by the protruding claw block. Which can avoid the impact of internal deformation and centrifugal force.Claw large concave convex,so that the involute tooth on the surface pressure is small. Even if the tooth to withstand the overload,the tooth still will not wear or deformation.

5.USE:main use for mining, chemical, lifting, textile, Industrial gear bitumen pump, fans, etc.

6.Axial plug in installation.

The following is the introduction of JS and JP two series couplings

| Model | Nominal torque

N.M |

Maximum Speed

rpm |

bore diameter

d1、d2 mm |

Bore length

L1、L2 mm |

L

mm |

D

mm |

D1,D2 mm |

E mm |

S mm | rotational inertia

kg.m^2 |

Weight

kg |

| JS1 | 20 | 19000 | 6-19 | 25 | 66 | 40 | 32 | 16 | 2 | 0.00008 | 0.30 |

| JS2 | 70 | 14000 | 8-24 | 30 | 78 | 55 | 40 | 18 | 2 | 0.0002 | 0.61 |

| JS3 | 190 | 11800 | 10-28 | 35 | 90 | 65 | 48 | 20 | 2.5 | 0.0007 | 1.00 |

| JS4 | 380 | 9500 | 12-38 | 45 | 114 | 80 | 66 | 24 | 3 | 0.002 | 2.08 |

| JS5 | 530 | 8000 | 14-42 | 50 | 126 | 95 | 75 | 26 | 3 | 0.004 | 3.21 |

| JS6 | 620 | 7100 | 15-48 | 56 | 140 | 105 | 85 | 28 | 3.5 | 0.006 | 4.41 |

| JS7 | 750 | 6300 | 20-55 | 65 | 160 | 120 | 98 | 30 | 4 | 0.012 | 6.64 |

| JS8 | 850 | 5600 | 22-65 | 75 | 185 | 135 | 115 | 35 | 4.5 | 0.025 | 10.13 |

| JS9 | 1950 | 4750 | 30-75 | 85 | 210 | 160 | 135 | 40 | 5 | 0.054 | 16.03 |

| JS10 | 4800 | 3750 | 40-90 | 100 | 245 | 200 | 160 | 45 | 5.5 | 0.139 | 27.50 |

| JS11 | 6800 | 3350 | 50-100 | 110 | 270 | 225 | 180 | 50 | 6 | 0.245 | 38.50 |

| JS12 | 8000 | 3000 | 60-110 | 120 | 295 | 255 | 200 | 50 | 6 | 0.435 | 54.0 |

| JS13 | 10000 | 2650 | 60-125 | 140 | 340 | 290 | 230 | 60 | 7 | 0.85 | 81.8 |

| JS14 | 14500 | 2380 | 60-140 | 155 | 375 | 320 | 255 | 65 | 7.5 | 1.4 | 109.7 |

| JS15 | 20000 | 2000 | 80-160 | 175 | 425 | 370 | 290 | 75 | 9 | 2.72 | 162.7 |

| JS16 | 23500 | 1800 | 85-180 | 195 | 475 | 420 | 325 | 85 | 10.5 | 4.95 | 230.8 |

| Model | Nominal torque (N.M) | Maximum speed

(r/min) |

bore diameter

d1 d2 dz (mm) |

Bore length

(mm) |

L0

(mm) |

D

(mm) |

D1

(mm) |

rotational inertia

(Kg.m2 ) |

Weight Kg | ||||

| (HA) | |||||||||||||

| a | b | c | iron | steel | Y | Z、J | |||||||

| ≥75 | ≥85 | ≥94 | L | L1 | |||||||||

| JP1 | 16 | 25 | 45 | 11500 | 15300 | 12 14 | 32 | 27 | 80 | 50 | 40 | 0.014 | 0.66 |

| 16 18 19 | 42 | 30 | 100 | ||||||||||

| 20 22 24 | 52 | 38 | 120 | ||||||||||

| JP2 | 63 | 100 | 200 | 8200 | 109 | 20 22 24 | 52 | 38 | 127 | 70 | 50 | 0.075 | 1.55 |

| 25 28 | 62 | 44 | 147 | ||||||||||

| 30 32 | 82 | 60 | 187 | ||||||||||

| JP3 | 90 | 140 | 280 | 6700 | 9000 | 22 24 | 52 | 38 | 128 | 85 | 60 | 0.178 | 2.5 |

| 25 28 | 62 | 44 | 148 | ||||||||||

| 30 32 35 38 | 82 | 60 | 188 | ||||||||||

| JP4 | 140 | 250 | 400 | 5500 | 7300 | 25 28 | 62 | 44 | 151 | 105 | 65 | 0.412 | 4.3 |

| 30 32 | 82 | 60 | 191 | ||||||||||

| 35 38 | |||||||||||||

| 40 42 | 112 | 84 | 251 | ||||||||||

| JP5 | 250 | 400 | 710 | 4600 | 6100 | 30 32 35 38 | 82 | 60 | 197 | 125 | 75 | 0.73 | 6.2 |

| 40 42 45 48 | 112 | 84 | 257 | ||||||||||

| JP6 | 400 | 630 | 1120 | 4000 | 5300 | 35*38* | 82 | 60 | 203 | 145 | 85 | 1.85 | 8.6 |

| 40*42* | 112 | 107 | 263 | ||||||||||

| 45 48 50 55 | |||||||||||||

| JP7 | 710 | 1120 | 2240 | 3400 | 4500 | 45*48*50*55* | 112 | 84 | 265 | 170 | 100 | 3.88 | 14.0 |

| 60 63 65 | 142 | 107 | 325 | ||||||||||

| JP8 | 1120 | 1800 | 3550 | 2900 | 3800 | 50*55* | 112 | 84 | 272 | 200 | 120 | 9.22 | 25.7 |

| 60 63 65 | 142 | 107 | 332 | ||||||||||

| 70 71 75 | |||||||||||||

| JP9 | 1800 | 2800 | 5600 | 2500 | 3300 | 60*63*65* | 142 | 107 | 334 | 230 | 150 | 18.95 | 41.0 |

| 70 71 75 | |||||||||||||

| 80 85 90 95 | 172 | 132 | 394 | ||||||||||

| JP10 | 2800 | 4500 | 9000 | 2200 | 2900 | 70*71*75* | 142 | 107 | 344 | 260 | 180 | 39.68 | 59.0 |

| 80 85*90 95 | 172 | 132 | 404 | ||||||||||

| 100 110 | 212 | 167 | 484 | ||||||||||

| JP11 | 4000 | 6300 | 12500 | 1900 | 2500 | 80*85*90*95* | 172 | 132 | 411 | 300 | 200 | 73.43 | 87.0 |

| 100 110 120 | 212 | 167 | 491 | ||||||||||

| JP12 | 7100 | 11200 | 20000 | 1600 | 2100 | 90*95* | 172 | 132 | 417 | 360 | 215 | 178.45 | 140 |

| 100*110*120*125* | 212 | 167 | 497 | ||||||||||

| 130 | 252 | 202 | 577 | ||||||||||

| JP13 | 8000 | 12500 | 25000 | 1400 | 1900 | 100*110*120*125* | 212 | 167 | 497 | 400 | 225 | 208.75 | 160 |

| 130*140* | 252 | 202 | 577 | ||||||||||

Coupling Shaft hole diameter with * can be use for the Model J Z.