OLDHAM COUPLING : Aluminum – Set Screw OC series ;Shaft Bore range:4,5,6, 6.35,7,8,9, 9.525 ,10,11,12,12.7 , 14,15,16,19,20,22,24,25,28,30,32,35 mm

1:Colloidal materials imporoted PA66,has good wear resistance.

2:Corrosion resistance and electrical insulation.

3:Sliding design more effective compensation of radial and angular misalignment.

4:Top tight type(set screw).

OC Series

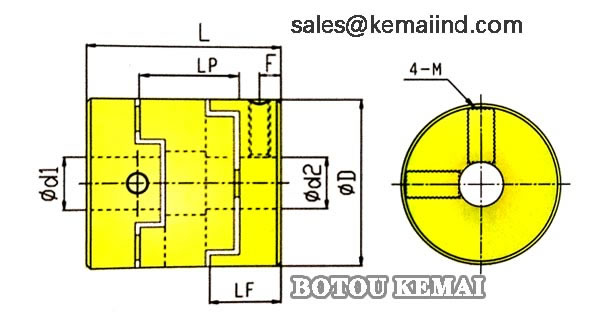

OC-Outside diameter X Total length – d1 bore X d2 bore

Example: OC-25X28-6X8

OC: Oldham Coupling

25: Outside diameter

28: Total length

6: d1 bore diameter

8: d2 bore diameter

| Model | d1 d2 bore | ΦD | L | LF | L1 | L2 | LP | F | M | Wrench Torque

(N.M) |

| OC-16X18 | 4,5,6, 6.35 | Φ16 | 18 | 7.25 | 7.25 | 3.9 | 11.6 | 3.35 | 4-M3X5 | 0.7 |

| OC-20X23 | 6, 6.35 ,7,8,9, 9.525 ,10 | Φ20 | 23 | 9.15 | 9.15 | 4 | 12.7 | 5.15 | 4-M4X5 | 1.7 |

| OC-25X28 | 6.35 ,7,8,9, 9.525 ,10,11,12 | Φ25 | 28 | 11.5 | 11.5 | 5.8 | 16.6 | 5.7 | 4-M4X6 | 1.7 |

| OC-32X33 | 8,9, 9.525 ,10,11,12, 12.7 , 14,15,16 | Φ32 | 33 | 13.75 | 13.75 | 7 | 19.5 | 6.75 | 4-M5X8 | 4 |

| OC-40X35 | 8,9, 9.525 ,10,11,12,14,15,16,18 | Φ40 | 35 | 15.1 | 15.1 | 6.8 | 18.4 | 8.3 | 4-M6X12 | 7 |

| OC-50X38 | 10,11,12, 12.7 , 14,15,16,19,20,22 | Φ50 | 38 | 19 | 19 | 7.5 | 15 | 5.75 | 4-M6X12 | 7 |

| OC-55X57 | 10,11,12, 12.7 , 14,15,16,19,20,22 | Φ55 | 57 | 28 | 28 | 9.5 | 20 | 9.25 | 4-M8X14 | 8.4 |

| OC-63X47 | 15,16,19,20,22,24,25 | Φ63 | 47 | 22.75 | 22.75 | 8 | 17.5 | 7.38 | 4-M8X14 | 8.4 |

| OC-70X57 | 19,20,22,24,25,28,30,32,35 | Φ70 | 57 | 27.5 | 27.5 | 8.5 | 19 | 9.5 | 4-M8X16 | 8.4 |

| Model | Rated torque

(N.M) |

Maximun

torque (N.M) |

Allow Radial direction

(mm) |

Allow angle

(°) |

Allow Axis

(mm) |

Maximum speed

(rpm) |

Static torsional stiffness

(N.M/rad) |

Moment of inertia

(kg.M2) |

Bushings Material | Flexible colloidal material | SurFace Treatment | Weight

(g) |

| OC-16X18 | 0.7 | 1.4 | 0.8 | 3 | +0.2 | 10000 | 30 | 3.3×10-7 | High strength aluminum alloy | PA66 | Oxidation treatment | 6 |

| OC-20X23 | 1.2 | 2.4 | 1 | 3 | +0.2 | 10000 | 58 | 1.1×10–4 | 15 | |||

| OC-25X28 | 2 | 4 | 1.2 | 3 | +0.2 | 10000 | 130 | 3.1×10–6 | 25 | |||

| OC-32X33 | 4.5 | 9 | 1.5 | 3 | +0.2 | 9000 | 270 | 9.6×10–5 | 44 | |||

| OC-40X35 | 9 | 18 | 1.8 | 3 | +0.2 | 7500 | 520 | 2.3×10–5 | 81 | |||

| OC-50X38 | 19 | 38 | 2 | 3 | +0.2 | 7000 | 800 | 1.8×10–4 | 142 | |||

| OC-55X57 | 25 | 50 | 2 | 3 | +0.2 | 6700 | 900 | 280 | ||||

| OC-63X47 | 33 | 66 | 2 | 3 | +0.2 | 6300 | 1200 | 6.3×10–4 | 320 | |||

| OC-70X57 | 36 | 72 | 2 | 3 | +0.2 | 6000 | 4800 | 430 |